Research

I intend to pursue a PhD in Mechanical Engineering in integrating renewable energy sources. My current or previous research experiences are listed below.

Parameter Optimization | Dr. Ankit Goel

November 2021 — Present

Background: Dr. Ankit Goel is an assistant professor at UMBC. He runs the Estimation, Control, and Learning Laboratory (ECLL) in the Mechanical Engineering department.

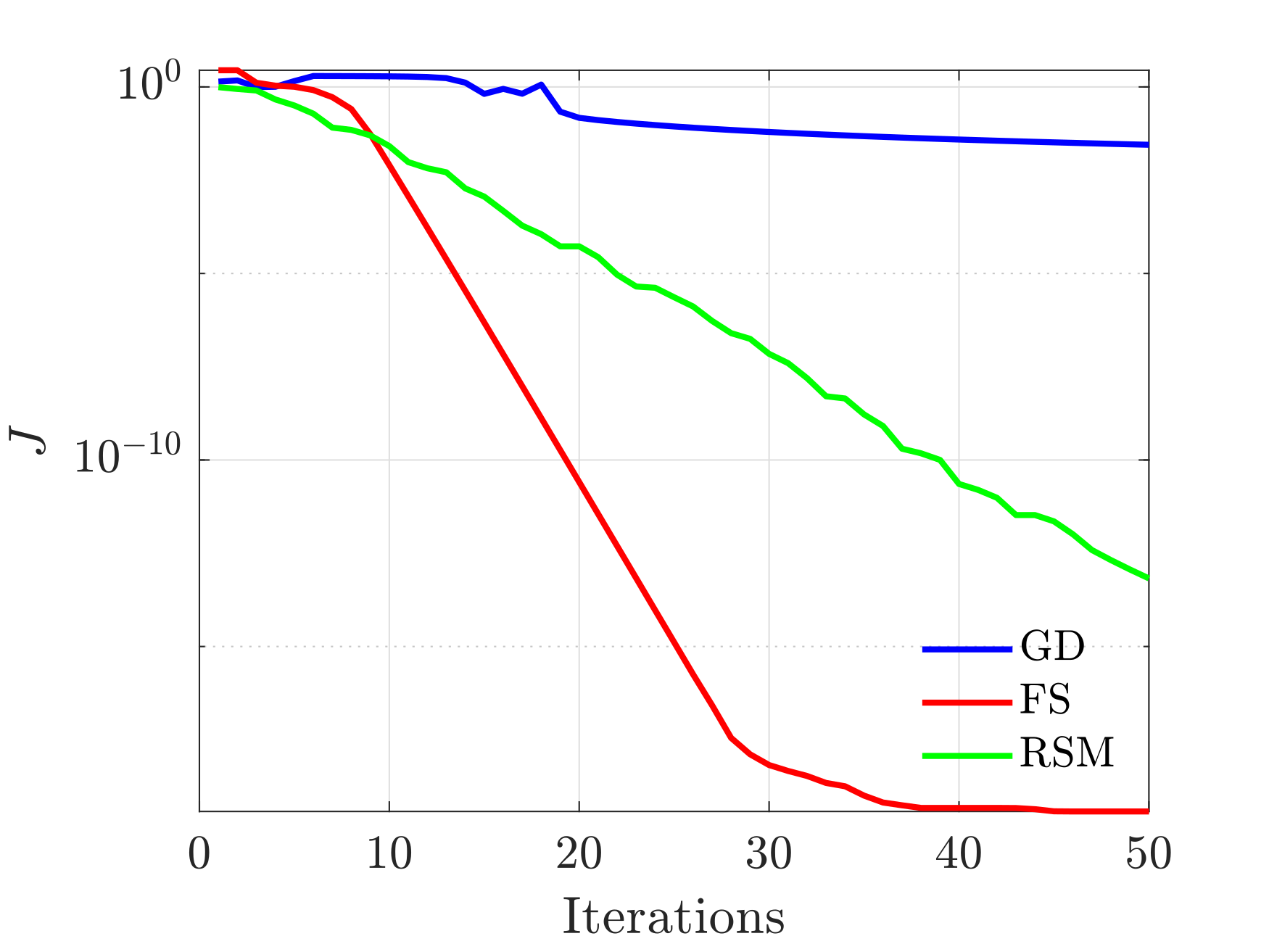

Figure 1: Testing gradient free training methods

such as

Figure 1: Testing gradient free training methods

such as fsolve and random search method

against conventional gradient descent in approximating the XOR function

using a NN.

I implement and test various optimization techniques to solve classical non-linear problems and train neural networks (NNs). In particular, I have,

- Used conventional machine learning techniques to train NNs using both Keras, Pytorch, and custom gradient descent,

- Illustrated the ability of gradient free methods, such as the Newtonian method and random search method, to surpass conventional gradient descent in training NNs, as shown in figure 1,

- Tested the effect on inertial measurement units due to properties of accelerometers, gyroscopes, and magnetometers,

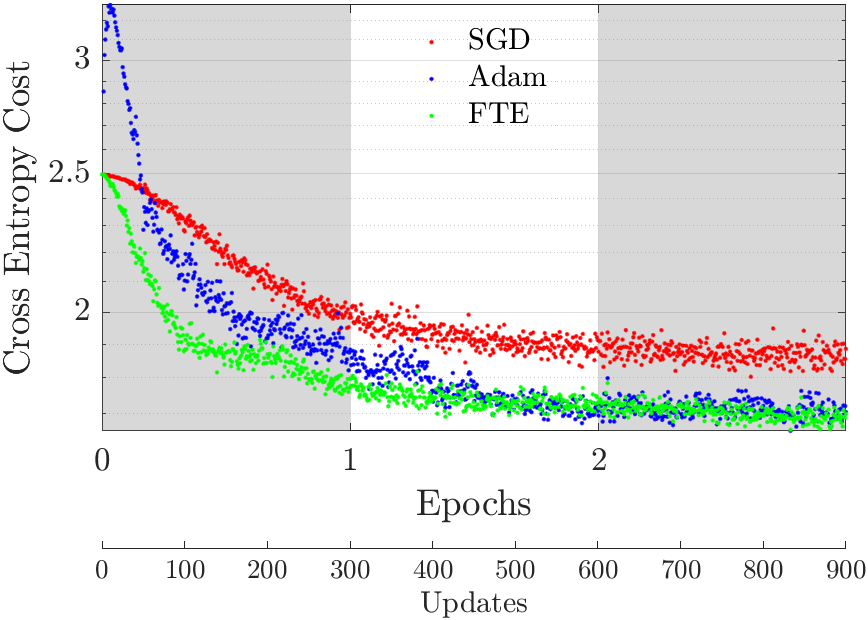

- Implemented a novel finite time algorithm in discreet problems such as NNs, shown in figure 2,

- Combined extended Kalman filter with NNs to improve long term convergence,

- And developed a simultaneous localization and mapping platform for future research and coursework.

Additionally, I had the opportunity to write on my work or present on my research:

-

Conference Paper, 2022

"A Tutorial on Neural Networks and Gradient-free Training"

Submitted to: 2024 American Controls Conference (ACC)

Status: Rejected

Authors: Turibius Rozario, Arjun Trivedi, Ankit Goel

arXiv link -

URCAD, 2023

Presented poster on neural networks and gradient-free training on UMBC's undergraduate research day. Link to abstracts - 2023. Time accelerated algorithms. This was cancelled due to thresholding.

-

URCAD, 2024

Modelling dynamical systems using neural networks. -

Conference Paper, 2024

"Matrix-Based Representations and Gradient-Free Algorithms for Neural Network Training".

Submitted to: 2024 International Conference on Machine Learning and Applications (ICMLA).

Status: Accepted

Authors: Turibius Rozario, Parham Oveissi, Ankit Goel -

Conference Paper, 2024

"Neural filtering for Neural Network-based Models of Dynamic Systems"

Submitted to: 2025 American Control Conference

Status: Under Review

Authors: Parham Oveissi, Turibius Rozario, Ankit Goel

arXiv link

Figure 2: Comparing training algorithm performance on MNIST dataset;

the finite time method was shown to outperform

conventional adaptive momentum and stochastic gradient descent methods

in this case.

Figure 2: Comparing training algorithm performance on MNIST dataset;

the finite time method was shown to outperform

conventional adaptive momentum and stochastic gradient descent methods

in this case.

Magnesium Extraction Methods from Seawater | Dr. Michael Wagner

Summer 2024 (REU)

Backgroud: Dr. Michael Wagner is a Mechanical Engineering professor at University of Wisconsin, Madison. He runs the Energy Systems Optimization Lab (ESOL) with a focus on applied research on developing simulation models and software, and methodologies of improving usage of sustainable energy sources or methods.

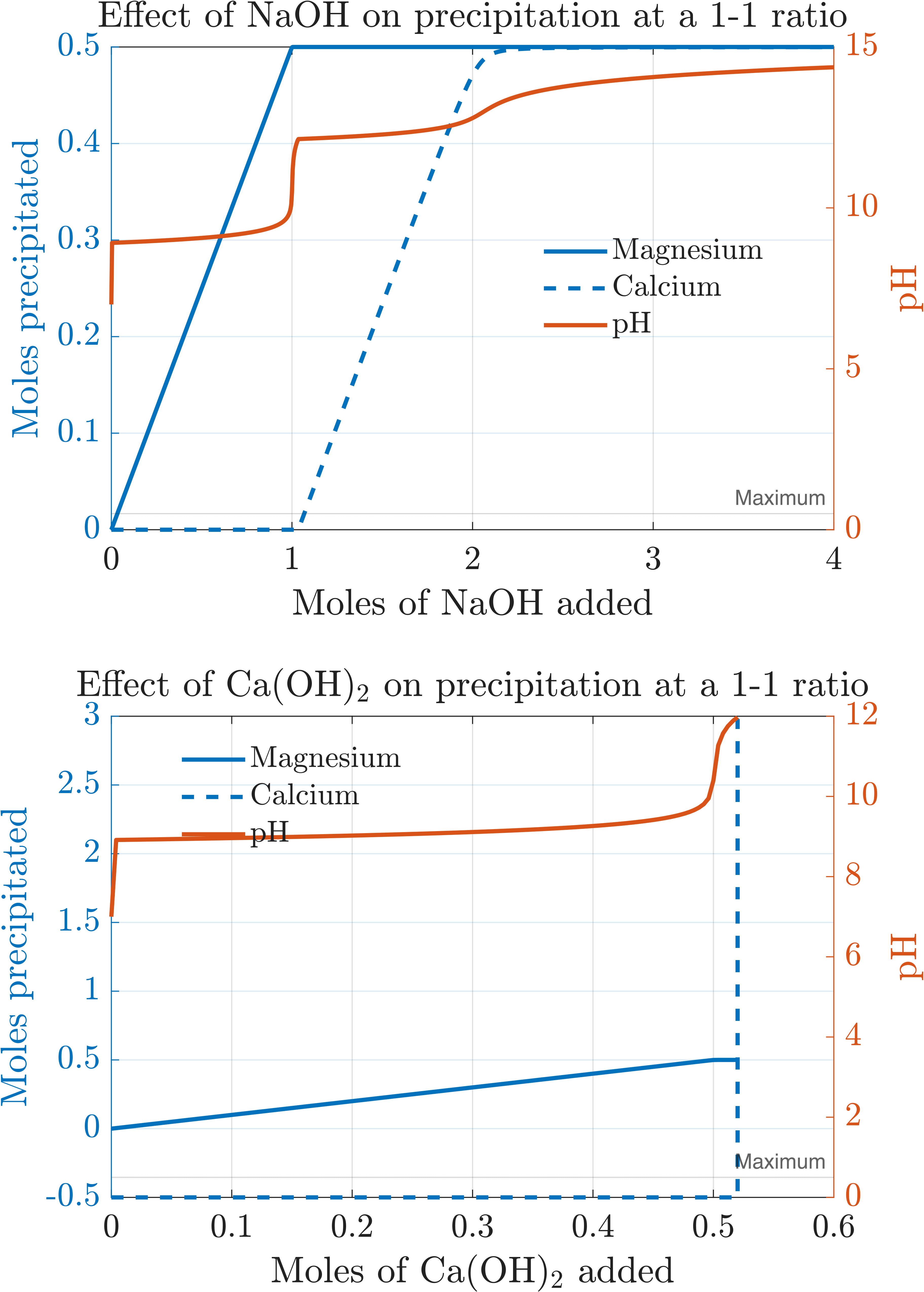

Figure 3: Effect of pH on magnesium hydroxide and calcium

hydroxide precipitate using sodium hydroxide or calcium

hydroxide as the base, as calculated using PHREEQC.

Figure 3: Effect of pH on magnesium hydroxide and calcium

hydroxide precipitate using sodium hydroxide or calcium

hydroxide as the base, as calculated using PHREEQC.

A seawater mining with zero-liquid discharge powered by nuclear energy was proposed by ESOL. Seawater would undergo pretreatment, all ions will be extracted, and finally reverse osmosis would provide fresh drinking water, all while being powered by sustainable nuclear energy.

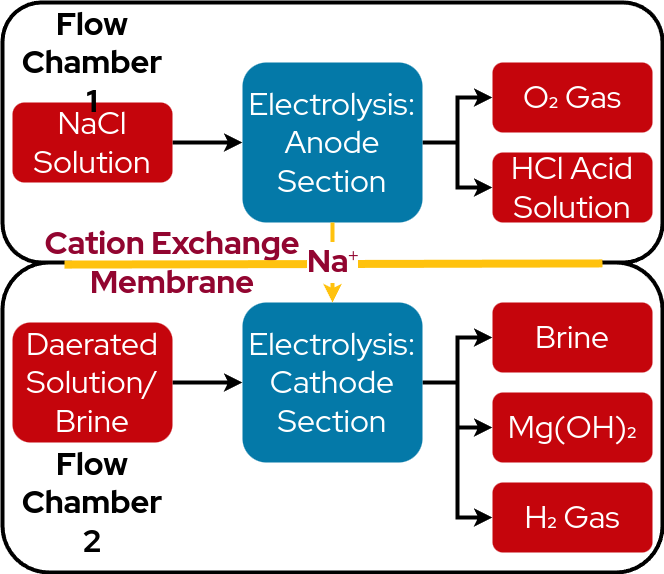

My role over the summer was researching the extraction of bivalent ions, primarily magnesium ions, from seawater. I determined and analyzed the energy and cost requirements for all the methods related with magnesium salt extraction and conversion to pure magnesium metal. Figure 3 showcases the utilization one of the methodologies that I had to test to determine its effectiveness, and figure 4 showcases a method by Sano et al. 2018. I went beyond and researched pre-treatment of seawater, extraction of calcium, and concentration of seawater and its inaccuracies.

Three deliverables were produced during this research experience:

- Research poster, presented at University of Wisconsin, Madison.

- Detailed documentation on extracting magnesium.

-

Journal Paper, 2024

"Perspectives on Advancing Seawater Desalination and Mining with Nuclear Energy"

Status: To be submitted to Desalination

Authors: Kristian Marril Bacarro, Elizabeth Keith, Turibius Rozario, Giovanny Morales Colón, Ben Lindley, Michael J. Wagner, Mark Anderson, Luca Mastropasqua, Mohan Qin

Figure 4: Visual illustration of magnesium hydroxide

Figure 4: Visual illustration of magnesium hydroxide

Design of a Lab-Scale Ocean Wave-Powered Desalination System | Dr. James Van de Ven

Summer 2023 (REU)

Background: Dr. James Van de Ven is a Mechanical Engineering professor at University of Minnesota. He runs the Mechanical Energy & Power Systems Laboratory (MEPS) with a focus on fluid power.

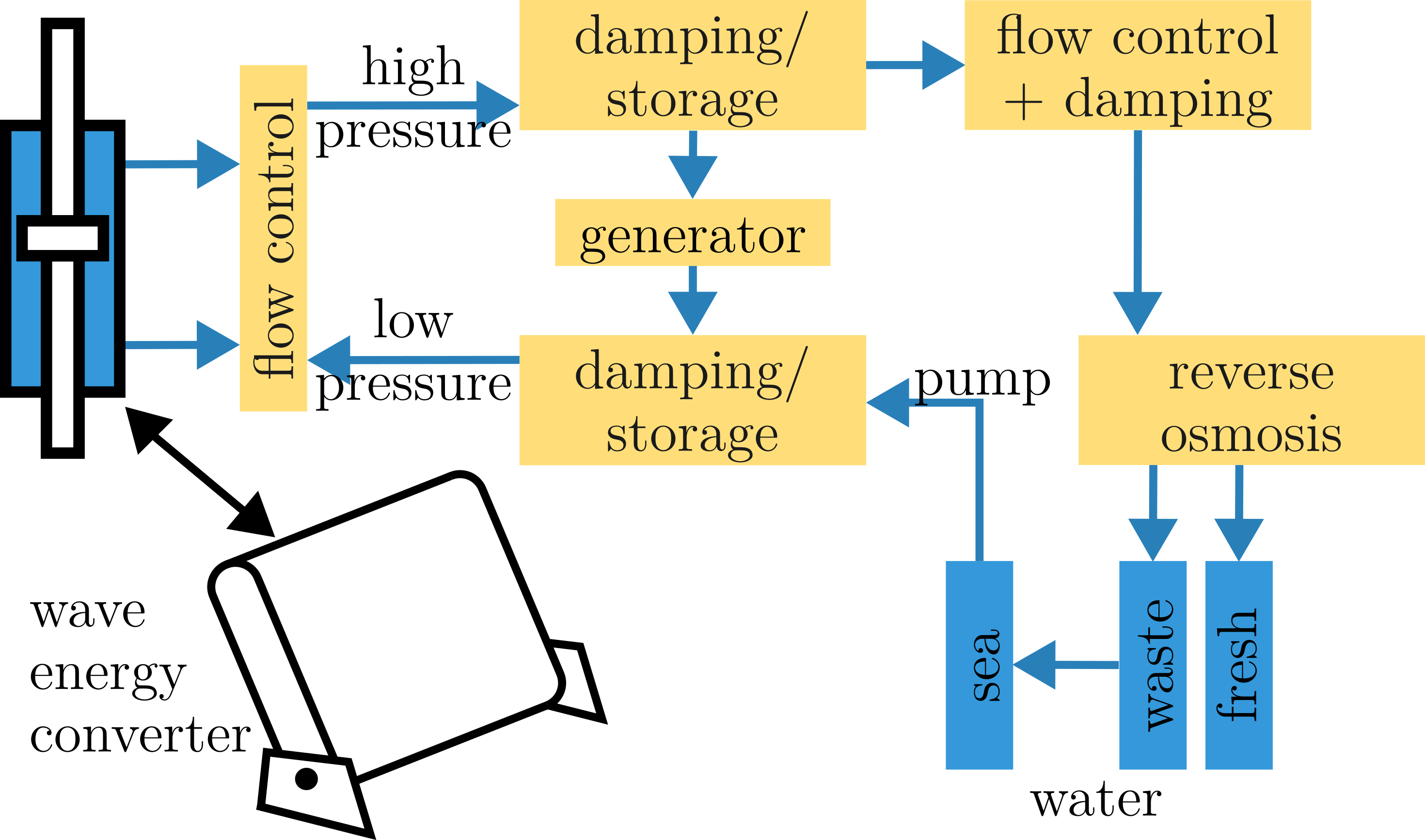

Figure 5: Illustration of the core processes and elements in

the desalination system.

Figure 5: Illustration of the core processes and elements in

the desalination system.

A self-powered and decentralized wave energy converter and desalination system was proposed in prior work by the MEPS lab. The wave energy is harvested using a large oscillating flap hinged at the sea bed, whose kinetic energy is then transferred into hydraulics; the pressurized seawater is used to generate electricity and freshwater. Figure 5 showcases these primary traits.

My role over the summer was to help scale this full-scale system to a lab-scale hardware-in-the-loop test system. With the help of my graduate mentor, Jeremy Simmons, I:

- Used fluid equations, efficiency computations, and dimension constraints to size the system.

- Identified parts required to construct the system and generated a bill of materials.

- Designed custom parts and fittings, and a draft assembly model.

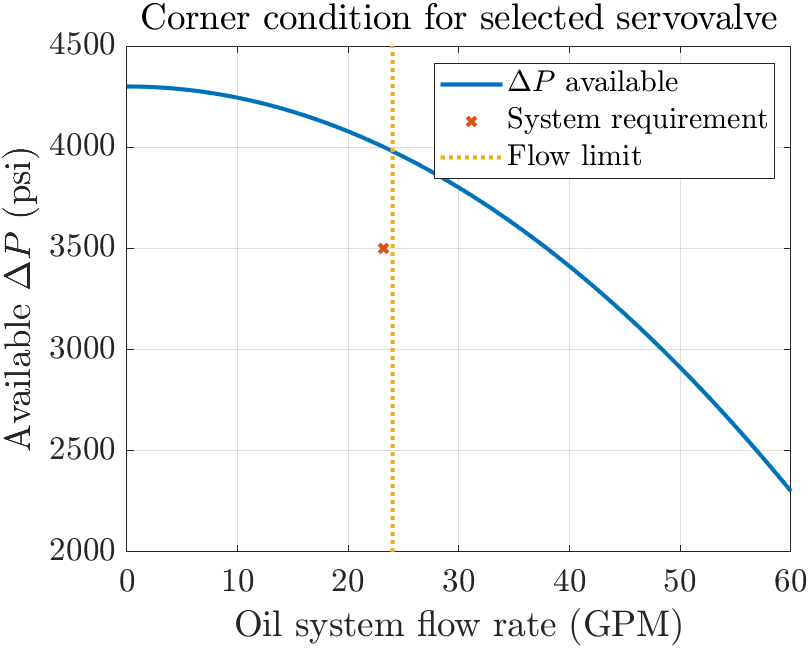

Figure 6 compares the maximum required pressure differential to the achievable pressure differential based on the energy losses through a specific servo valve; the maximum required flow rate is compared against the achievable flow of the pump. Performance evaluations such as this helped determine whether the combination of the chosen parts would be capable of simulating the motion of the wave energy converter.

Three deliverables were produced during this research experience:

- Research poster, presented at SURE at University of Minnesota. Link to abstracts.

- Extended abstract, which can be read here

- Project hand-off memo, consisting of all research files and deliverables.

Figure 6: Maximum system requirements for pressure differential and flow rates compared

to the achievable pressure differential (4300 psi supply) and flow rate.

Figure 6: Maximum system requirements for pressure differential and flow rates compared

to the achievable pressure differential (4300 psi supply) and flow rate.

This page was last updated on December 10, 2024